Since 1999, vitaAER and its technology partners have designed, manufactured, supplied, installed and commissioned in excess of a hundred biological, chemical and physical odour control systems throughout South and Southern Africa.

Odour control technologies for treating municipal wastewater odours are typically classified as biological (bio-trickling filters, biofilters and bioscrubbers), chemical (dry scrubbers and wet scrubbers) or physical (carbon adsorbers and photo-ionisation) systems.

Each of these systems has strengths and weaknesses and selecting the appropriate technology depends on the details of the application and the specific needs of the customer.

Selecting an appropriate odour control technology and sizing an odour control system for a particular application require careful consideration of the following factors:

- Physical and chemical characteristics of the odours

- Odour concentrations

- Required odour removal efficiency

- Required foul air extraction rate

- Available space

- Water availability

- Effluent discharge requirements

- Electrical requirements

- Maintenance requirements and available resources

- Life cycle costs

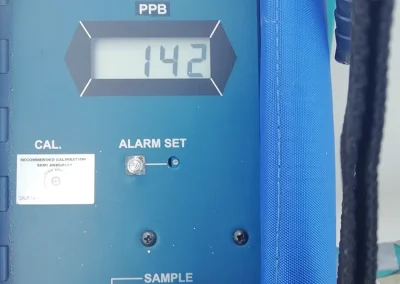

Odour control systems are sized based on foul air extraction rates, odour mass loading and required odour removal performance. The foul air extraction (air treatment rate) is based on the peak air displacement rate (liters/s or m³/h) from a pump station wet well during filling plus a safety factor (i.e. 20-30%). Odour concentrations are determined by recording H₂S concentrations (used as a signature odour) with loggers over a time-period (typically 7 to 14 days under worst case conditions).

Based on our experience and drawing on worldwide industry know-how we believe that bio-trickling filters and dry scrubbers are the most appropriate technologies for treating odours typically associated with sewage pump stations.

Bio-trickling filters have the lowest life cycle cost of all available technologies and have the least impact on the environment. In addition, they require relatively limited maintenance and can operate without operator intervention for extended periods. The economic advantage increases as mass loadings and the system size increase due to economies of scale.

For smaller/lower mass loading applications, dry scrubbers are ideal because they are compact and virtually maintenance-free. Dry scrubbers can run for years without any maintenance and require no operator intervention. However, dry scrubbers become less economical as mass loadings and the system size increase.

Although vitaAER also offers wet scrubbers, carbon adsorbers and photo-ionisation systems, the disadvantages associated with these systems make them mostly unsuitable for treatment of sewage pump station odours. Wet scrubbers require continuous replenishment and dosing of hazardous chemicals and require constant maintenance. Carbon adsorbers are by far the most expensive of all technologies due to the cost of regular carbon replacement. Photo-ionisation systems are also expensive to operate due to the cost of replacing UV-lamps and catalyst every 12 to 18 months.

For effective and economic odour control at sewage pump stations vitaAER therefor recommends bio-trickling filters for pump stations where average H₂S concentrations exceed 15 ppm and dry scrubbers for treating lower average H₂S concentrations.